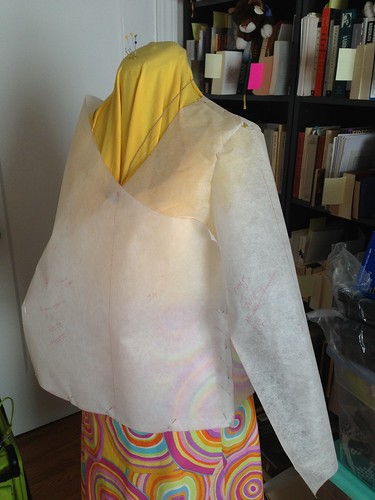

Thoughts while I worked on muslin #1:

1. The fabric is plasticky and see through - this is not a wearable muslin, why am I still reluctant to write on it?

2. Must find better way of sewing knits. Tested straight stitch and pulled seams. They all popped. Switched to zig zag, but was too big, so could see "teeth" in the seams.

3. Stick to using the walking foot. Use the more narrow twin needle (must find the sizes). The wider twin needle created a huge tunnel between the stitches.

4. Neckline - while I did an impressive* job of stitching and easing, it was too tight for the design, so in the end, both fronts are pulling the side seams in. I examined a garment that is similar and the neckline is not a separate piece, it's just folded over and stitched down with presumably an elastic tape inside.

Muslin #2:

1. Will use a 1" seam on the neckline, folded over at 1/2" with elastic tape inside.

2. Front panel must be hemmed before sewing side seams.

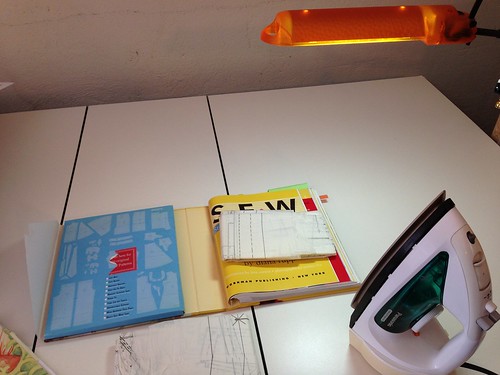

3. Finish watching

The Ultimate T-Shirt: Fitting & Construction on Craftsy and put the tips and tricks to use. Just watching how the knit fabric can be fed through the sewing machine with minimal use of pins has already helped enormously. Considering that the Ottobre pattern directions are minimalist, it's really good to bone up on how to construct a knit t-shirt. Even though this garment is a wrap front, 90% of the sewing tips and instructions still apply. I got my class on sale and it came with a pattern,

Vogue 8793, which I have yet to take out of the envelope.

4. Will baste the side seams before final sewing. Very important when trying to get the wrap tight enough to cross over without gaping, but not so tight that it pulls the sides in.

5. I started cutting muslin #2 on Sunday, 7/28, but after I cut the back, I realized that I already didn't follow my own modified directions - that is, to include a 1" seam allowance on the neckline. Hope that there's enough fabric to cut a sleeve from the back. Also realized that my rotary cutting technique could use some improvement, so off to search for tips. Must also change the blade on the cutter. Don't know how long the blade has been on there, and technically haven't cut much with it, but think it might be a bit dull.

6. Before sewing, need to do another clean out of the sewing machine. While sewing muslin #1, the machine coughed up a greasy lint hairball which was subsequently sewn down into the sleeve seam. I have no idea where it came from, as I had recently cleaned (as far as I know) everything out. Very strange. Thank god the muslin wasn't anything I had hoped to wear. Will also see if I can clean the grease spot, for science. Just in case it happens when I'm sewing my good fabric.

7. Hemming of sleeves and bottom - not until side seams are sewn up. Follow the tips in the class re: pressing the hems while still flat.

Thoughts on muslins in general: apparently Kenneth King states that you should sew at least two muslins before proceding to cut the fashion fabric. Reluctantly, I concede that this makes perfect sense. If you want something truly wearable, you must put in the time and effort to do it right. Think about it - you pull a pattern from the envelope, and regardless of how close it may be to your measurements, more likely than not, it wasn't custom drafted for you. You'll need to make fitting alterations and perhaps even figure out how best to sew it - thus muslin #1. But, after figuring out what to keep and what to change, including order of construction, you should test the next round on muslin #2. You don't know what the outcome of the changes from muslin #1 are going to give you. Only after sewing a successful, i.e. potentially wearable muslin #2, can you proceed with confidence to the final garment. Thank god I really am a process sewer (knitter) or I would have already torn out every last strand of my short hair in frustration!

*I don't normally brag about my sewing...but considering I only watched the Ultimate T-Shirt video and had never sewn a neckline, and that this is my fifth garment (including muslins), the neckline looks awesome.